Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

86-0519-85506598

Project

1. Overview

Hot blast furnace is a heating and blowing equipment for blast furnace (high furnace), it is an indispensable part of modern blast furnace. Modern blast furnaces mostly use regenerative hot blast stoves, whose working principle is to burn gas first, heat the grid bricks of the regenerator chamber with the generated flue gas, and then heat the cold air from the blast station through the hot grid bricks. The hot blast stove is burned and blown alternately, so that the blast furnace can continuously obtain high-temperature hot air. The temperature of hot blast stove vault is an important data for safe and accurate operation of hot blast stove.

Temperature of traditional hot blast stove is measured by thermocouple. The armored double platinum rhodium thermocouple or other thermocouple is used to indirectly control the hot air temperature by measuring the temperature of the insulation wall.

Conditions in furnace are always tough alone with high temperature and high pressure. Limited to the requirements of operation environment and instrument’s structure, thermocouple thermometry would result in inaccurate measurement and lag reaction when works in harsh condition such as frequently temperature changes, large pressure fluctuations and event in vibration.

Since a thermocouple works at the high temperature of 1200 ℃ ~ 1400 ℃ in furnace for long term, the thermocouple junction box also works at high temperature between 100 ℃ to 120 ℃, which will dramatically reduce instrument’s service life to a range from few weeks to few months. It will increases use-cost and maintenance workload.

In order to overcome above shortcomings, our company has designed and produced a serials of specialized infrared temperature measure device to ensure our infrared temperature measuring system works reliably in complex environment.

2. System block diagram

Targets to hot blast stove applications in metallurgical industry, our company develops a series of two-color infrared pyrometer suitable for the corresponding environment. The design is equipped with a sealed heat-insulating window and a special protection device. The main device adopts flange connection (can be customized according to user requirements), which can be easily connected to the vault or side equipment. The unique dirty lens warning function can ensure the continuous and reliable operation of the equipment.

Infrared pyrometer determines the temperature of the hot air by measuring the temperature of the checker brick. The infrared pyrometer outputs a 4~20mA current signal or RS485 signal corresponding to the temperature processing by computer or recorder. The two-color infrared pyrometer can reduce the influence of factors such as different emissivity, dust, water vapor and fog at the measurement site, changes in distance, and partial obscuration of objects on the measured temperature. It can increase the reliability of the system and reduce the cost of maintenance.

3. Product features

◇ Temperature measurement range 600℃~1800℃

◇ Temperature measurement accuracy 0.5%, repeat accuracy 2℃, resolution 0.1℃

◇ Response time 5ms~99.99s, adjustable

◇ Use manual adjustable focus lens, standard The focusing distance is 0.35m to infinity

◇ Use PID constant temperature control for the detector, comes with full-scale temperature compensation to avoid the influence of ambient temperature on measurement accuracy.

◇ Both two-color and one-color temperature measurement mode, switchable

◇ Visual aiming is adopted to clearly show the position and size of the measured target

◇ Industrial-grade OLED screen is used as the display interface, and the man-machine interface is friendly

◇ Abundant peripheral interfaces: 2 independent analog output, 2 alarm output, 1 level output and 1 RS485 communication interface.

◇ Software and hardware and other anti-interference designed to improve system stability and can resist 2500VDC pulse group interference

◇ Built-in angle adjustment mechanism (install angle can be fine-tuned), ball valve (convenient for users to use and maintain), mounting flange, and one-way valve (to prevent high-temperature gas from backstreaming).

◇ 10mm thick high temperature quartz protection lens, with lens heating function (prevent lens condensation and avoid the influence of water vapor on the measurement result).

◇ Dirty lens warning function, when the lens is too dirty, a warning is issued in advance to ensure the continuous and reliable operation of equipment.

◇ The whole structure is made of 304 stainless steel, part of the material is made of 316L (to improve the corrosion resistance of the equipment), the whole set of equipment is sturdy and durable.

◇ Design lifetime 5-10 years , reduce the cost of equipment.

4. The advantages of two-color pyrometer compared with one-color pyrometer

In two-color temperature measurement, temperature will not change with the object's surface state (such as different surface roughness or chemical state ), which will not affect the accuracy of temperature measurement, but will have an impact on one-color pyrometer measurement .

The optical part of pyrometer, such as glass, will accumulate some dust after using for a period. The presence of water, gas, oil, etc. in the air will reduce the emissivity coefficient, so the temperature measured by one color pyrometer will decrease. The two-color pyrometer measures the ratio of infrared radiation intensities of two band wavelength in a specific range. With dust, water vapor and other disturbances, the signals of two wavelength fall simultaneously and the ratio remains constant after division. But this does not mean two-color pyrometer does not require maintenance. User still need to wipe the glass when it is too dirty.

One-color pyrometer cannot measure objects smaller than the field of view. When the target cannot fill the field of view, the measurement temperature will be lower than actual temperature. The two-color pyrometer can measure objects smaller than the field of view, and can eliminate the influence of water vapor, dust, changes of detection target size, partial obscuration, and emissivity changes. A two-color pyrometer does not need to correct the two-color coefficient when measuring most gray body materials. The two-color pyrometer measures the average value of the highest temperature in an area.

Two-color infrared pyrometer of SIJIE OPTOELETRONICS can overcome the effects of severe water vapor, dust, detection target size changes, partial obstruction, and emissivity changes. Even if the detection signal is attenuated by 95%, it will not have any impact on the temperature measurement results. Unique software algorithm can overcome the influence of oxide layer. The hardware and software design is suitable for the processing of one million times of the signal, which can meet the user's demand for instrument accuracy, repeatability and so on.

5. System configuration list

|

No |

Product name |

Specifications and models |

Unit |

Quantity |

Remarks |

|

1 |

Two-color infrared thermometer |

BFS-STRONG |

Taiwan |

1 |

Temperature measurement range is 600℃~1800℃, temperature measurement accuracy is 0.5%, Temperature resolution is 0.1℃, the distance coefficient is 100:1, Visual aiming, with a water-cooling and air purge protective cover. |

|

2 |

BFS protective cover (customized) |

BFS-01 |

Taiwan |

1 |

Built-in angle adjustment mechanism, ball valve, mounting flange, one-way valve, quartz protective lens, with lens heating function, The whole structure is made of 304 stainless steel, and some materials are made of 316L, which is sturdy and durable. |

|

3 |

Junction box |

CON-01 |

Taiwan |

1 |

Default is a cast aluminum junction box, and an outdoor waterproof 304 control box can be selected according to user needs. |

Note: According to user needs, could add acousto-optic alarm, photoelectric isolation type RS485 to USB converter, color paperless recorder, industrial control computer. The power supply is above DC24V/2A (heating coil power is 10W, acousto-optic alarm power is 10W, power consumption of the pyrometer is 5W, and the whole set of equipment uses DC24V power supply to improve the safety of the system).

6. System parameters

(1) Pyrometer technical parameters

| Model | BFS-STRONG-SR-6018 |

| Temperature measurement range | 600℃~1800℃ |

| Detector | Si/Si (Laminated Silicon) |

| Monochrome working wavelength | 1.08μm |

| Colorimetric working wavelength | Wavelength 1: (0.7~1.08)μm; Wavelength 2: 1.08μm |

| Main application |

Hot rolled, wire rod, metal forging, casting, induction heating, molten glass, Cement kiln, semiconductor, vacuum furnace, polysilicon, monocrystalline silicon, hot blast stove temperature measurement system |

| Distance factor | 100:1 |

| Measure distance | 0.45m to infinity adjustable |

| Measurement accuracy | ±0.5%T (T is the reading temperature) |

| Resolution | 0.1℃ |

| Repeat accuracy | ±2℃ |

| Monochrome factor | 0.100~1.100, step distance 0.001 is adjustable. |

| Two-color coefficient | 0.850~1.150, adjustable step distance of 0.001. |

| Response time | The fastest 5ms, 5ms-99.99s adjustable |

| Signal processing | Peak value, bottom value, average value, high and low ambient temperature alarm, single color, two color switchable, power failure protection and other functions |

| Output |

Group 1: multiple analog output (4mA~20mA, 0mA~20mA, 0V~5V, 0V~10V can be switched), The output resolution is 16bit, accurate to 0.1℃, the current loop output maximum load is 600Ω, the voltage output allows the current 10mA |

| Group 2: of analog output 4mA~20mA, resolution 16bit, accurate to 0.1℃, current loop output maximum load 600Ω | |

|

Alarm output: upper limit and lower limit alarm, using optocoupler relay to have unlimited service life, On-resistance ≤2Ω, maximum allowable voltage AC42V or DC60V, maximum allowable current 120mA, response time 2ms |

|

| PNP level output (output current 100mA, with overload protection) | |

| RS485 output, which can realize parameter modification, data recording and query functions | |

| Display mode | Using industrial-grade self-luminous OLED display screen |

| Power supply |

DC (20~30)V, with overvoltage, overcurrent, and short circuit protection, power consumption: 5W (24V@200mA) Built-in EMI filter can resist the interference of 2500VDC pulse group. |

| Environmental temperature compensation | Built-in 40℃ constant temperature heater, built-in full temperature compensation, temperature measurement accuracy is almost not affected by ambient temperature. |

| Aim method | Eyepiece aiming |

| Interface | Imported sealed plug and 12-core high temperature shielded cable |

|

Thermometer Use environment |

Without water cooling: -20℃~+60℃, purge pressure is 0.1MPa, flow rate is 6L/ min With water cooling: -20℃~+200℃, cooling water pressure is 0.2MPa, flow rate is 2L/min |

| Protection level | IP65 |

(2) Wiring table

| Brown | Red | Orange | Yellow | Green | Blue | Purple | Gray | White | Black | Pink | Dark blue |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| +24V | 0V | Multiple Analog |

(4~20) mA |

Output signal ground wire |

PNP Output |

COMH | NOH | COML | NOL | A | B |

| Power input | Analog output | Upper limit alarm output | Lower limit alarm output | RS485 communication interface | |||||||

Multiple 16Bit analog output:(4~20) mA, (0~20) mA, (0~5) V, (0~10) V alternative,default(4~20)mA. PNP output is dirty lens alarm output.

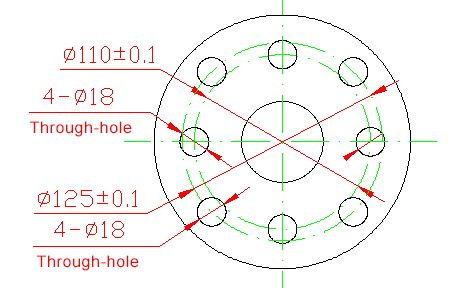

(3) Flange installation dimensions

Suitable for DN40 or DN50 stainless steel flanges, DN40 flanges are preferred.

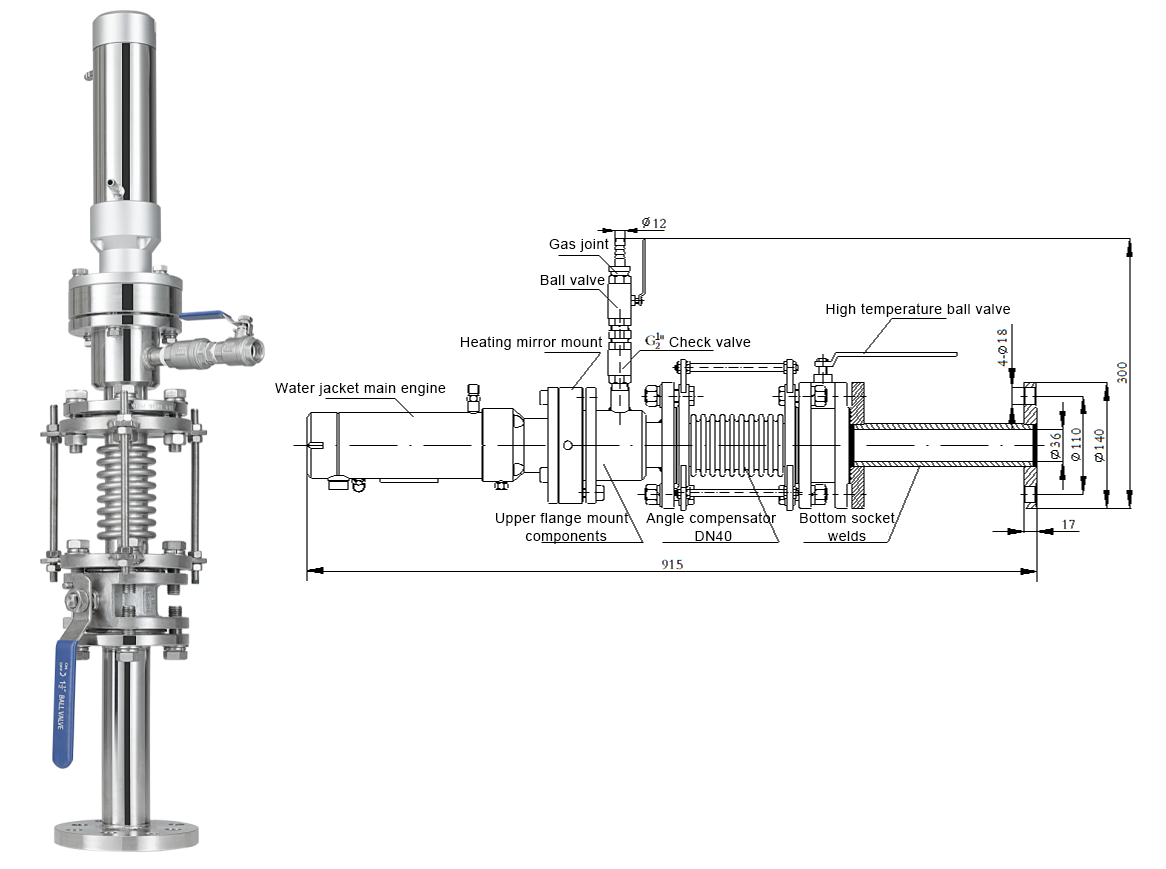

(4)Host structure diagram

(5) Host plus junction box

7. System configuration requirements

Currently, there are two ways are used to install hot blast stove infrared pyrometer, one is installed from the stove vault aim to checker brick, and the other is installed on the side of stove aim to checker brick. According to the user's process requirements to determine the installation method and the approximate installation angle. Determine size of the hot blast stove connection flange and pyrometer connection. Configure according to requirements:

(1) Cooling gas source: pressure is 0.1MPa, and the φ10 (outer diameter) hose is connected to pyrometer

(2) Purge air source: pressure is 0.5MPa, clean instrument air source, φ12mm (outer diameter) metal smooth pipe connection, the pressure must be greater than the pressure in hot blast stove.

(3) Air source system components include pressure reducing valves, filters, and pressure gauges, all can be configured according to spot requirements. When there is no need of air purge, air source system components do not need to be installed.

Recommended product selection:

STRONG-SR-6016 hot-blast stove infrared thermometer movement.

BFS-STRONG-SR-6016 is used to detect the temperature of hot blast stove.

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.