Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

86-0519-85506598

Project

1. Overview

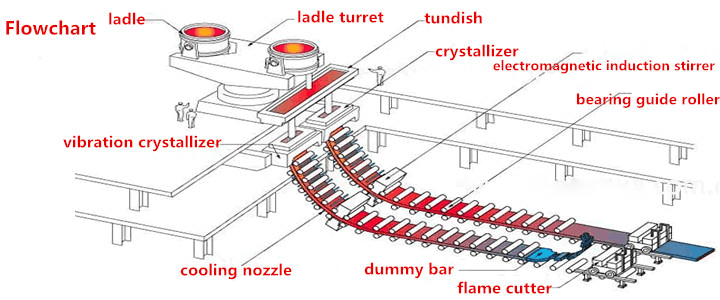

At present, infrared temperature measurement systems have been widely used in various occasions in metallurgical production lines. However, when measuring the temperature of slab in continuous casting machine in the second cooling zone, the problems of measurement accuracy and system reliability always exist. In order to improve the accuracy of slab surface temperature measurement. Changzhou Sijie summarizes various problems reported by users and proposes the following infrared temperature measurement solutions:

2. Various factors affecting slab temperature measurement

(1) Surface condition

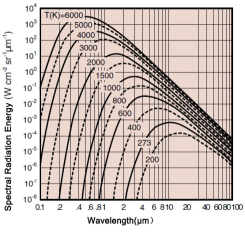

The measurement object is tainless steel, and the measrement result is related the emissivity and oxidation degree of the surface. If the object surface is smooth, the object emissivity is 0.05-0.5. If the degree of oxidation of the surface increases, the emissivity will also increase. When the oxidize film on the surface is above 10um, the emissivity tends to be stable.

The use of monochromatic temperature measurement result will be affected by changes in emissivity, especially when measuring stainless steel, the changes in emissivity have a great impact on the temperature measurement results, and if use a two-color thermometer to measure the temperature, the result will not be affected by emissivity. When measuring metal materials similar to stainless steel, the thermometer only need to be calibrated once.

(2) Effects of radiation

Casting blank has high temperature and large volume. The surrounding temperature is also very high, but regular instrument can only stand with temperautre under 85℃, and recommended to use in the site which temperature is under 50℃. In this situation, need to use fiber optical pyrometer which senser probe and detector is separated. Sensor probe can withstand high temperature up to 250°C without cooling. The detector is installed in a place where the ambient temperature is relatively low. When the ambient temperature is high,the probe can also be cooled by water,it could greatly improve the service life of the instrument.

(3) Iron oxide scale

The influence of scale on the temperature measurement results can be avoided using a special software algorithm. To judge the emissivity characteristics of the oxide skin, the sampling time of the system must be fast enough (more than 10ms), the signal needs to be collected synchronously without delay, and the collected signal must be selected. The comprehensive application of various software algorithms can avoid the influence of oxide skin on the temperature measurement accuracy.

(4) Moisture and dust in the optical channel

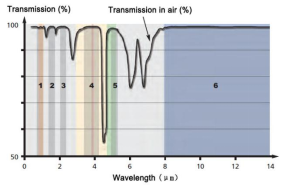

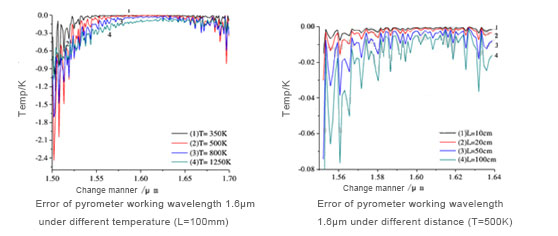

Using a two-color thermometer can basically avoid the influence of water vapor and dust. Even if the signal of the measured object is attenuated by 95%, it will not affect the temperature measurement accuracy. Choosing a dual-wavelength pyrometer in the 0.8-1um band can avoid the influence of water vapor. Water vapor is basically transparent in the 0.8-1um band. Use relevant data to explain the influence of water vapor on temperature measurement at different measurement distances and measurement temperatures.

Combined with relevant data, the influence of water vapor on temperature measurement under different measurement distances and temperatures is described.

Change manner of emissivity of water vapor with the wavelength of 0.8-1.0μm varies is similar to absorption change manner of water vapor with the wavelength of 1.6μm, which is almost "transparent" absorption band of water vapor. Therefore, the error of the pyrometer with operating wavelength of 0.8-1.0μm is almost negligible.

The influence of water vapor and certain dust on two-color pyrometer is basically negligible, but to completely avoid influence of these factors, an extension rod is designed and compressed air is added to keep optical channel clean. Just need to keep a distance of 20cm between pyrometer and the thickest measuring slab. In this way, the equipment is basically maintenance-free.

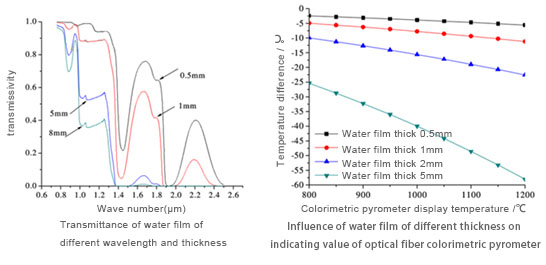

(5) The influence of water film on slab surface

Temperature measurement accuracy of infrared pyrometer is related to the mist of water film on slab surface. The thicker the water film medium, the more attenuation of the radiation energy of surface. Refer to following documents:

Because of the impact of cooling water, there are certain water accumulation areas and certain water film in the casting slab in the second cold zone of continuous casting. Even if a two-color pyrometer is used, these areas should be avoided as much as possible. In the actual measurement, a two-color pyrometer below 1.1um is selected for measurement and the temperature is corrected.

3. Advantage of two color pyrometer over one color pyrometer

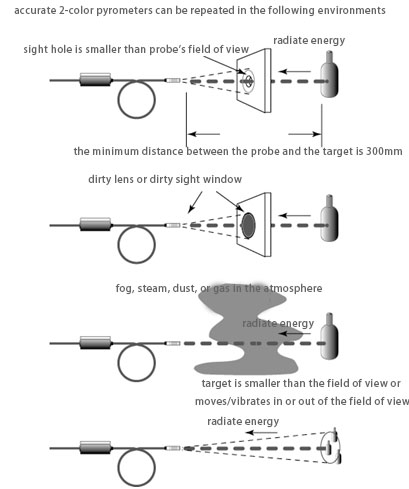

In two-color temperature measurement, temperature will not change with the object’s surface state (such different surface roughness or chemical state ), which will not affect the accuracy of temperature measurement, but will have an impact on one-color pyrometer measurement .

The optical part of pyrometer, such as glass, will accumulate some dust after using for a period. The presence of water, gas, oil, etc. in the air will reduce the emissivity coefficient, so the temperature measured by one color pyrometer will decrease. The two-color pyrometer measures the ratio of infrared radiation intensities of two band wavelength in a specific range. With dust, water vapor and other disturbances, the signals of two wavelength fall simultaneously and the ratio remains constant after division. But this does not mean two-color pyrometer does not require maintenance. User still need to wipe the glass when it is too dirty.

One-color pyrometer cannot measure objects smaller than the field of view. When the target cannot fill the field of view, the measurement temperature will be lower than actual temperature. The two-color pyrometer can measure objects smaller than the field of view.

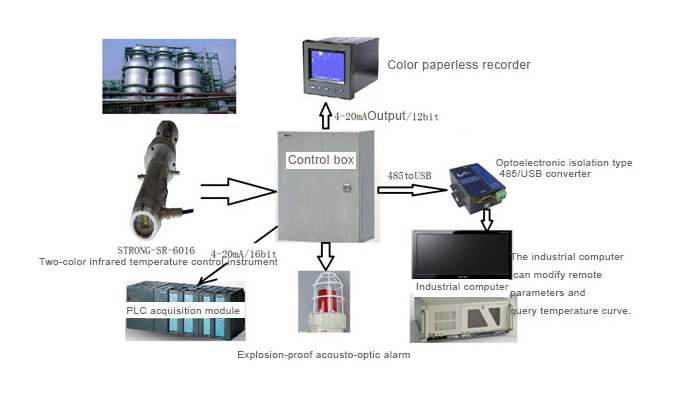

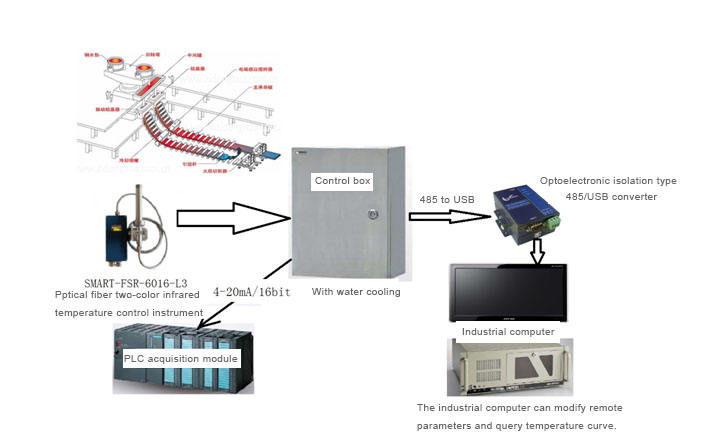

4. System block diagram

The controller is equipped with water cooling. In order to improve the use safety, it is recommended to use DC24V power supply, and each power supply is not less than 10W. Optical fiber and cable are protected by high temperature asbestos, to be done on site. Each detector must be equipped with purging and water cooling to ensure the reliable operation of the system for a long time.

5. System configuration list

|

Product name |

Model specifications |

|

Optical fiber two-color |

SMART-FSR0600℃10.1℃,测温范围60.5%,温度3℃~10.1℃,带宽保护窗,6000.6米,光纤长3米 |

|

不锈钢304 |

SJ-01控制箱,可接水冷,防护等级IP65 |

推荐产品选择:

SMART-FSR-6016-L3

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.