Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

86-0519-85506598

Project

1. Overview

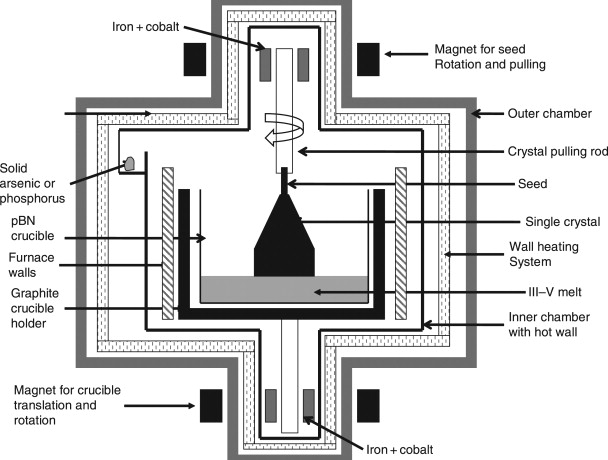

Single crystal silicon is widely used in various fields such as semiconductors, solar cells, integrated circuits, and discrete components. Polycrystalline silicon is a raw material for the production of monocrystalline silicon, and the purity of monocrystalline silicon is much higher than that of polycrystalline silicon. The purity of monocrystalline silicon is generally 99.99999%, and can even reach 9N or more than 12N. At present, the Czochralski method is mostly used in domestic and abroad to obtain single crystal silicon.

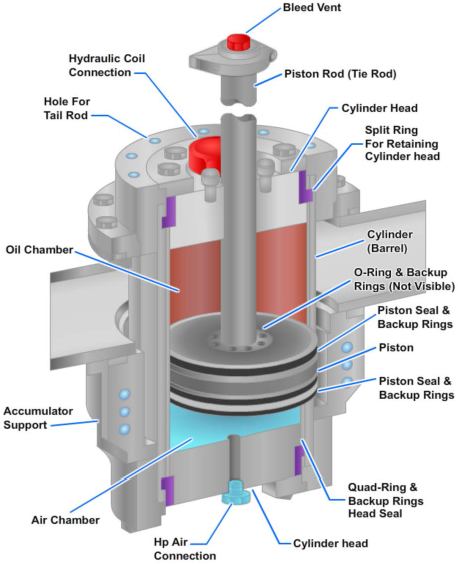

Czochralski single crystal furnace is composed of mechanical part and electrical part. The mechanical part includes water cooling system, argon system, vacuum system, furnace body, thermal system, and hydraulic system. The electrical part includes speed control unit, heating control unit, heating temperature control and three-phase full bridge power components, equal diameter growth controller, water temperature inspection and status alarm, and relay control unit. (Cited textbook literature.)

The thermal system of the czochralski single crystal furnace is used to melt the single crystal silicon material and maintain the entire system of single crystal silicon growth at a certain temperature.

The heater is an important part of the thermal system, it is a direct heating element, and the temperature can reach up to 1600°C. The graphite crucible is used to hold the quartz crucible, and the single crystal silicon is contained in the quartz crucible.

The infrared pyrometer measures the surface temperature of the graphite crucible and the temperature of the monocrystalline silicon liquid surface, and superimposes the signal from the isodiameter controller temperature controller, and then feeds it back to the temperature control system.

2. Infrared temperature measurement of monocrystalline silicon

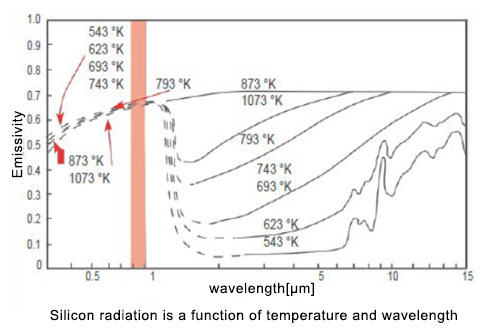

Silicon materials are relatively difficult to detect. The corresponding relationship between silicon radiation temperature and emissivity is shown in the figure above. The emissivity of silicon is constant in a certain area. The infrared pyrometer is required to use a special narrow-band color filter to reduce the influence of emissivity changes.

(1) Single crystal silicon liquid surface temperature measurement

A short-wavelength two-color pyrometer is used to measure the temperature of the monocrystalline silicon liquid surface. Recommended product: STRONG-SR-7018 (link to STRONG series two-color infrared pyrometer), temperature resolution is 0.1℃, temperature resolution is 0.1℃, small changes in the temperature field can respond quickly, and have extremely high stability when measuring temperature.

The method of colorimetric temperature measurement can avoid the influence of silicon material diameter changes. The pollution of the window will not affect the accuracy of temperature measurement. It also has a dirty lens detection function. When the lens is too dirty, it will give a signal in advance to ensure the reliable operation of the system.

The features of STRONG-SR-7018 products are as follows:

Temperature measurement accuracy can reach 0.5%, the repeat accuracy is 2℃, and the temperature resolution can reach 0.1℃ (16bit)

The response time is 10ms~99.99s adjustable

Adopting adjustable focus lens, measuring distance from 0.35m to infinity

PID constant temperature control is used for the detector to eliminate the influence of ambient temperature on the measurement

Visual eyepiece, clearly show the position and size of the measured target

Both two-color and one-color temperature measurement function

In the two-color mode, there is a dirty lens detection function

Using industrial-grade OLED screen as the display interface, friendly man-machine interface

Software and hardware anti-interference design improves system stability and can resist 2500VDC pulse group interference

When the extract purity of single crystal silicon is high, coils will be placed around the single crystal furnace to ensure the stability of the magnetic field. Or when there is an explosion-proof requirement in the application, it is recommended to use a fiber-optic two-color infrared pyrometer in the area where the liquid level is measured. Recommended product: SMART-FSR-7018 (link to SMART series fiber optic two-color pyrometer). It adopts adjustable focus lens and red laser light source to aim, temperature resolution is 0.1℃, and it has extremely high temperature stability. The colorimetric temperature measurement method can avoid the influence of the diameter change of the silicon material. The pollution of the window will not affect the accuracy of temperature measurement. It also has a dirty lens detection function. When the lens is too dirty, it will give a signal in advance to ensure the reliable operation of the system.

(2) Detection of graphite crucible temperature

A short-wavelength one-color pyrometer is used to measure the temperature of the graphite crucible. Recommended product: STRONG-S-7022 (link to STRONG series one-color infrared pyrometer) or economic product MARS-S-6020 (link to MARS series one-color infrared pyrometer).

The two products use 1:1 green light source to aim at the target, and use adjustable focus lens (not limited by the installation distance), the temperature resolution is 0.1 ℃, and it has extremely high stability when measuring temperature.

When the extract purity of single crystal silicon is high, coils will be placed around the single crystal furnace to ensure the stability of the magnetic field. Or when there is an explosion-proof requirement in the application, it is recommended to use a fiber-optic one-color infrared pyrometer in the area of the graphite crucible. Recommended product: SMART-FS-7022 (link SMART series optical fiber one-color pyrometer). Using adjustable focus lens and laser light source for aiming, the temperature resolution is 0.1℃, and it has extremely high stability when measuring temperature.

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.